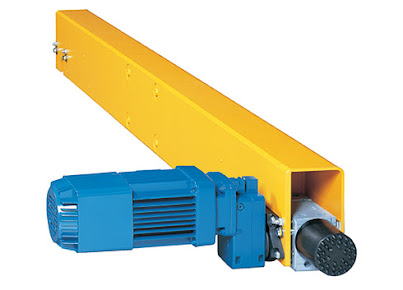

When it comes to the efficient operation of overhead cranes and other lifting systems, the end carriage plays a crucial role. End carriages support and facilitate the smooth movement of the crane along its runway, significantly impacting the overall performance and safety of the system. Selecting the right end carriage involves careful consideration of various factors to ensure optimal performance. Here’s a comprehensive guide to help you navigate through the essential factors in end carriage selection.

1. Load Capacity and Design Requirements

The first and most critical factor to consider is the load capacity of the end carriage. The end carriage must be designed to handle the maximum load that your crane will be lifting. This includes not only the weight of the loads but also any additional dynamic forces that may be encountered during operation.

- Load Rating: Ensure that the end carriage is rated for the maximum load it will support. This rating should align with the specifications of your crane system to avoid overloading and potential failures.

- Design Specifications: Evaluate the design specifications, including the material strength and structural integrity. End carriages should be constructed from high-quality materials such as steel or reinforced alloys to ensure durability and reliability.

2. Compatibility with Crane System

End carriages must be compatible with the specific crane system they will be used with. This compatibility affects the ease of installation, alignment, and overall performance of the crane.

- Track Compatibility: Check that the end carriage is designed to work with the type of track system installed in your facility. There are various types of track systems, including monorail, double girder, and single girder, and the end carriage should be compatible with your setup.

- Connection Mechanisms: Ensure that the end carriage features appropriate connection mechanisms for your crane system. This includes checking the mounting options and alignment features to guarantee a secure and stable fit.

3. Wheel Configuration and Quality

The wheels of the end carriage are a critical component that impacts the smoothness of movement and overall operational efficiency.

- Wheel Material: Wheels should be made from durable materials such as steel or cast iron to withstand the stresses of lifting operations. For specific applications, high-quality polyurethane or other composite materials might be preferred for their noise reduction and wear resistance.

- Wheel Size and Configuration: The size and configuration of the wheels should match the track system and load requirements. Properly sized wheels help distribute the load evenly and reduce wear and tear on the tracks and carriage.

4. Environmental Conditions

The operating environment plays a significant role in end carriage selection. Factors such as temperature extremes, humidity, and exposure to chemicals can affect the performance and longevity of the end carriage.

- Temperature Tolerance: Ensure that the end carriage is suitable for the temperature range of your operating environment. Some end carriages are designed to operate in extreme temperatures, either hot or cold.

- Corrosion Resistance: If your facility has high humidity or corrosive substances, choose an end carriage with corrosion-resistant coatings or materials. This helps prolong the lifespan of the equipment and maintain performance.

5. Maintenance and Serviceability

Ease of maintenance is another important factor to consider. Regular maintenance is essential to keep the end carriage and crane system operating smoothly and safely.

- Access Points: Look for end carriages with accessible maintenance points for lubrication, inspection, and adjustments. This simplifies routine upkeep and minimizes downtime.

- Replaceable Components: Check if the end carriage has components that can be easily replaced or serviced. This can be particularly useful for parts like wheels and bearings that experience regular wear and tear.

6. Safety Features

Safety should always be a top priority when selecting an end carriage. Proper safety features help prevent accidents and ensure safe operation.

- Braking Systems: Verify that the end carriage includes reliable braking systems to prevent uncontrolled movement. This is crucial for maintaining stability and safety during operations.

- Safety Locks: Some end carriages come with safety locks or other mechanisms to secure the crane in place when not in use. These features add an extra layer of safety by preventing accidental movements.

7. Cost and Budget Considerations

Finally, consider the cost and budget for the end carriage. While it’s important to choose a high-quality and reliable end carriage, it should also fit within your budget constraints.

- Initial Cost vs. Long-Term Value: Weigh the initial cost of the end carriage against its long-term value. Investing in a higher-quality end carriage may lead to lower maintenance costs and greater reliability over time.

- Total Cost of Ownership: Consider the total cost of ownership, including installation, maintenance, and potential downtime costs. A more expensive end carriage may provide better overall value if it reduces long-term operational costs.

Conclusion

Selecting the right end carriage is essential for the efficient and safe operation of overhead cranes and lifting systems. By considering factors such as load capacity, compatibility, wheel quality, environmental conditions, maintenance needs, safety features, and budget, you can make an informed decision that ensures optimal performance and longevity of your crane system. Investing time and resources in proper end carriage selection will pay off in the form of reliable and efficient lifting operations, contributing to the overall success of your facility’s operations.